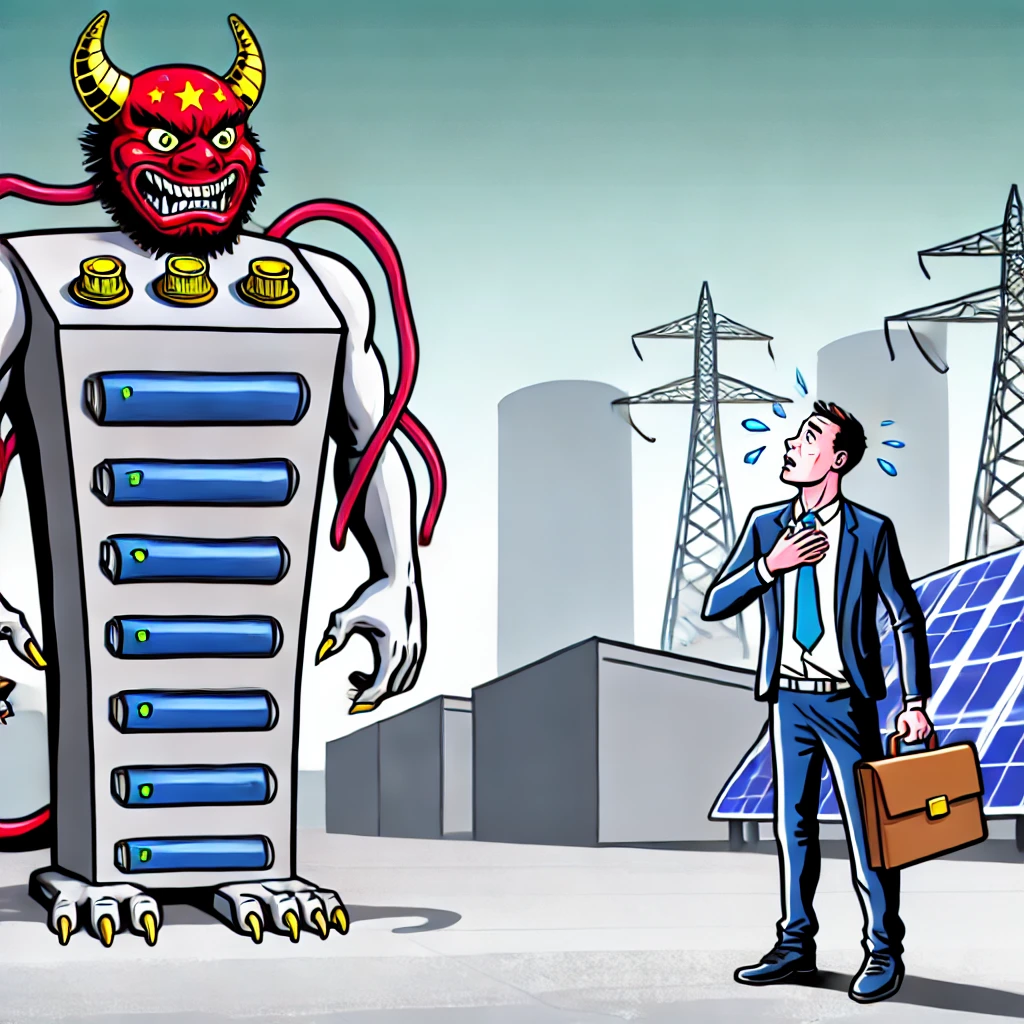

China’s leadership in the lithium-ion battery industry is a result of multiple interwoven factors. Central to this dominance is robust government support. Substantial subsidies and favourable regulations have fuelled rapid growth, while strategic investments in research and development have driven technological advancements. This proactive stance has enabled Chinese manufacturers to stay ahead in innovation and production capabilities.

An integrated supply chain further bolsters China’s position. Controlling a significant portion of the global supply of critical raw materials like lithium, cobalt, and nickel, China benefits from vertical integration, reducing dependency on external sources and enhancing efficiency. Large-scale production capabilities have also allowed Chinese companies to capitalize on economies of scale, lowering costs and increasing competitiveness.

Technological prowess is another key factor. Continuous R&D investments and collaborations with leading academic institutions have led to significant improvements in battery chemistry, energy density, safety, and lifecycle. Adoption of advanced manufacturing techniques, such as automation and AI, has enhanced production quality and efficiency.

Market demand within China plays a crucial role as well. As the largest market for electric vehicles and with strong initiatives in renewable energy, domestic demand for lithium-ion batteries remains high. Additionally, a thriving consumer electronics market further drives the industry’s growth.

Cost competitiveness, aided by lower labour costs and government subsidies, allows Chinese manufacturers to offer competitive pricing. Strategic global expansion through international partnerships, acquisitions, and strong export capabilities has extended their market reach.

Lastly, a skilled workforce, strengthened by educational initiatives, supports the high-tech demands of the industry. Together, these factors create a formidable foundation for China’s leadership in the global lithium-ion battery market.

While the Chinese lithium-ion battery industry holds a significant lead, it is feasible for other regions to catch up or even leapfrog through strategic innovation, government support, supply chain diversification, advanced manufacturing, and sustainability efforts. By leveraging the right strategies, manufacturers outside China can position themselves as competitive players in the global lithium-ion battery market.

For those who are a new entrants it might be better to skip the current lithium-ion technology and focus on industrializing next-generation energy storage solutions. In addition to all the above, a larger and strategic investment in R&D would be required. While challenging, the potential rewards include establishing a leadership position in the emerging energy storage market and driving the future of clean energy.

We have developed a decision-making framework that can help you pick the best strategic path for your company.